Step 1 Check and Clean

1.1. Remove all the impurities and debris from gasket, fasteners (Bolts, Studs, Nuts) and washers;

1.2. Check all fasteners and washers, make sure they are free of defects like burrs and cracks;

1.3. Check the flange surfaces, make sure they are free of defects which will impact the seal function of gasket, likes warpage, radial scratches and hit marks;

1.4. Any defects components should be replaced.

Step 2 Align Flanges:

2.1 Make sure the flanges and bolts' holes coaxial coincide;

2.2 Min flange gap is 10mm;

2.3 Insert the gasket parallel and carefully;

2.4 Do not use jointing compounds, grease or lubricants with gasket and flange surface. these compounds can affect the friction between the gasket and the flange and can lead to premature joint filure.

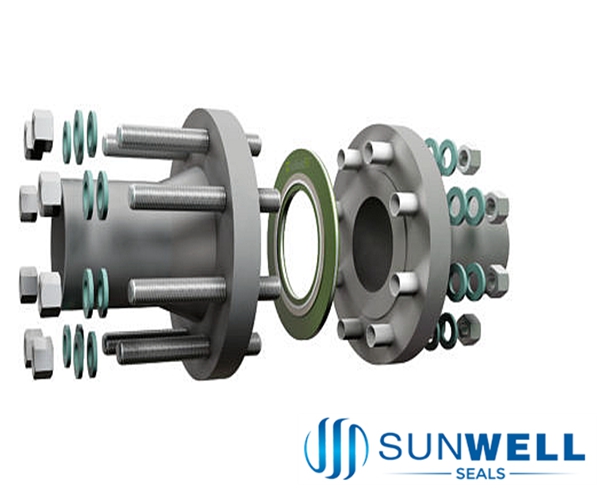

Step 3 Install Washer Kits

3.1 Apply bolt lubricant to the bolt and nut threads and to the face of nut to be tightened, assembly the steel washer, insulation washer and insulation sleeve to the bolts by turn (Make sure the steel washer always close to the nut);

3.2 Insert the bolts holes, no force used (like hammer), it will damage the sleeves. Please check the alignment of flange surface and size of sleeve if installation it's difficult;

3.3 Put insulator washer, steel washer and nut into bolts on another side of flange. Tighten all the bolts until the flange meet the gasket.

Step 4 Install Flange Kits

4.1 Please use calibrated torque wrench or other tool which have control functions;

4.2 Be installed in accordance with the recommended torque. (See SUNWELL SEALS Torque Chart);